Welcome to The Merchant Life – the newsletter where over 800 retail pros gain valuable merchandising insights and the insider perspective of all things retail.

We’re writing this as we travel through Europe, going from London to Milan. Nostaglic is the journey as Liza’s retail career started in the UK when she worked on the shop floor at Harrods. Eventually, working a stone’s throw away from the famed Saville Row at Ralph Lauren’s corporate office in Mayfair.

Naturally, one must be a bit flexible when travelling – delays, cancellations, and long lines are easier to deal with that way.

Also, flexibility is the theme for this newsletter.

Specifically, we’re talking about:

- How the concept of flexibilty is applied within product creation.

- Why this is an important concept.

- How being flexible gets brands faster to market.

Grab the yoga mat and towel, time to get your flex on.

Get Loose

Whether in recently published articles or back issues of the newsletter, you have seen our take on speed to market and what contributes to slowing that process down. 1

A few bullets to catch you up:

- It’s not uncommon for a brand to take at least 52 weeks to bring a product from concept to market.

- Most brands don’t leverage digital tools when creating materials or products.

- Retailers tend to overbuy and overproduce product, leading to markdowns.

So far, we have discussed this in general terms, commenting on all types of product categories – apparel, footwear, furniture and more – almost as if they were equal.

Further, within categories, we haven’t discussed specifics about the products being created; essentially, a shirt is a shirt is a shirt.

Oddly enough, retailers and brands are apparently looking at products in the same way.

More importantly, this point of view slows down speed to market.

Stretch and Hold

There is such thing as “acceptable inequality.”

For example, within the context of customer loyalty, not all customers should be treated equally.

Product creation has it’s own acceptable inequality too:

Products are unequal to begin with. So, not all products should be created equally.

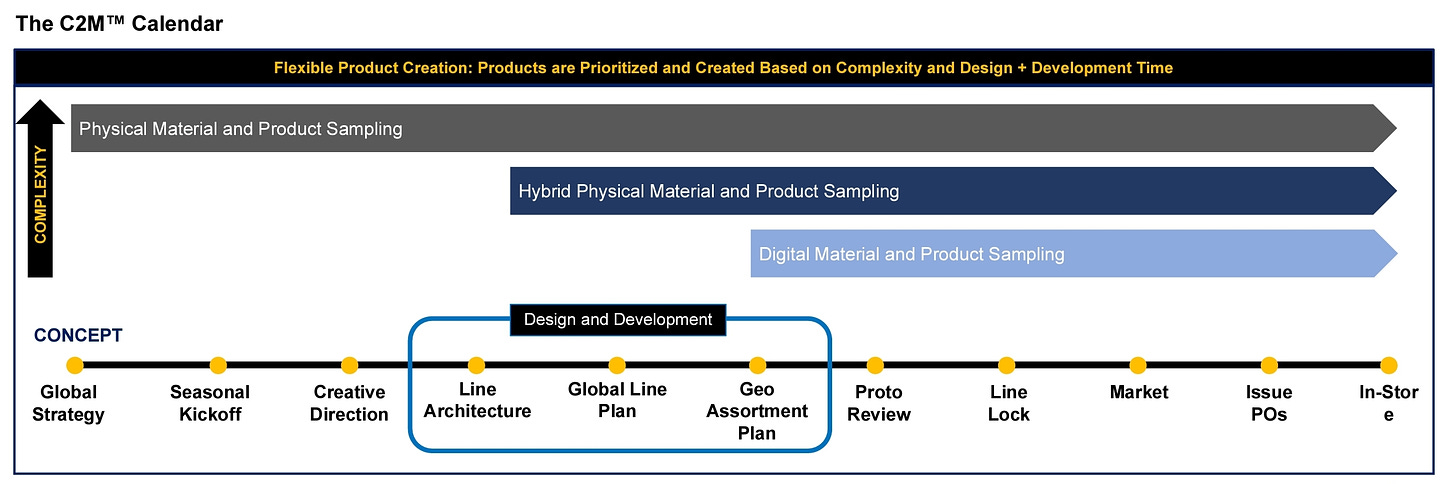

Look at the diagram below, outlining the traditonal C2M (Concept to Market) calendar:

Products are created in the same way, regardless of the complexity – from design and development to prototyping and sampling.

Trouble arises when we recognize that similar effort, time and resources are allocated to every product.

There is a bias towards strict physical sampling of the product. Digital protoyping and sampling is essentially absent.

Finally, the process starts and ends at the same time, and milestone moments are identical.

That means, regardless if we are talking about:

- A basic black t-shirt brought into market season after season with no changes.

- A rejuvenated polo shirt with a newly added front pocket.

- A brand new technical jacket that’s never been seen before, designed in response to increasing customer interest in the outdoors.

The approach to creating each is essentially the same.

But, no doubt, the products are unequal.

Don’t Stop My Flex

Because different products may need more or less testing, prototyping and sampling, flexibility in the product creation process accomodates the differences.

So, we introduce the concept of Flexible Product Creation (FPC) in the diagram below.

Consider our examples from above:

- The basic, black t-shirt is the least complex. Since this is a seasonless item, there isn’t much to review here. This should fly through the concept to market process with no physical development.

- The polo shirt is slightly more complex with the addition of a front pocket. Digital product development is the way to go, unless there is a material change where a physical prototype is useful to evaluate fit.

- The most complex product is the technical jacket. As this is brand new, physical sampling is required. How does it feel? How does it drape and fit? Technical attributes like warmth, water resistance and/or durability need testing as well.

The intention is that teams are flexible in how they approach creating product. Core silhouette, refreshed style or innovative product – teams know how best to get it done versus viewing everything as a nail with hammer in hand.

Also, start/stop dates and milestone moments will differ – the jacket will have more defined moments in the calendar versus the core tee.

Building Flexibility

If brands want to consider this approach to product creation, it first requires a mindset shift to have a chance of success.

The idea that physical samples are not needed is alien for some. They subscribe to the cult of “No Sample, No Sale” which is nonsense: if we can’t have a physical sample of the product we are buying into, then we are not buying at all.2

The hurdle of “We have always done it this way” must also be cleared. It’s also not uncommon to find teams working in isolation, defending their turf by being resistant to change – which is exactly what hinders progress.3

Next, flexibility in assortment planning has to be done intentionally, right at the start of the calendar. Retro-fitting a solution onto a calendar in progress could be more complicated than needed.

So, how does a brand proceed from here?

Here are three steps to start:

Step 1: Define the Merchandising Strategy

When determining the seasonal direction at concept, define the merchandising strategy. Quantify the product mix in buckets including seasonless/core, repeats and newness.

Most time will be spent on newness or updated styles which need testing, fitting and sampling.

Step 2: Line Plan Development

Develop the framework of the product mix and determine what styles must be physically sampled. Such product requires the most development effort and may include new material development.

Once the physical sampling direction is set, the rest of the FPC strategy is determined. Connect the remainder of the product mix to either hybrid development, digital development or no proto/sampling required.

Step 3: Product Strategy Alignment

Here, the frequency of when and how often teams meet for review and approvals is determined. This removes unnecessary “busy work” for carryover/seasonless styles and frees up time to invest into products that need it the most. Guardrails for design teams are enabled here, ensuring that they hit their deadlines.

Time’s Up

The main benefits of using FPC are all related to time. Specifically, time savings arise from eliminating physical sampling, review meetings and excessive approvals.

With time being freed up, valuable hours can be re-directed to higher priority work. This includes: developing innovative products, folding in customer insights and quickly trashing low performers from the assortment.

As an example, we had a conversation with the Head of Product Strategy and Operations at a major global brand. They shared that teams take far too long to deliver innovative products to market. So much so, their innovation process boils down to copying the competition. Product creation is already slow to begin with, so when innovative products are released, competitors have already blazed a path to the next big thing.

This is exactly why FPC is useful – creating space where truly innovate products are born. Doing so faster, in a way that is aligned with the brand and responsive to customers.

There is another significant, intangible benefit here as well.

The morale of the teams creating the product.

Brands have told us that a major driver of evolving the way they work is preserving the mental health of their teams.

Flexibility is not only a better way to develop product, it’s a better way to support the people developing product.4

Measuring Up

We get what FPC means, the intention behind it, steps to get started and some of the benefits.

Now, if a brand starts using FPC, how will they know it’s working?

Since the main benefits are related to time, we need instances where time windows are narrowed.

For example:

- Reducing time to approval and time to market compared to previous seasons.

- Increased time in market of product thus increasing the likelihood of selling at full-price.

- Eliminating unecessary travel and shipping when physical sampling is either scrapped or replaced by digital means.

- Adherence to deadlines increases a.k.a the goalpost stops moving.

As these measures accumulate, they translate into dollars. Specifically, increases in both full-price sales and gross margin – the main measures of success in accelerating speed to market.

Your CFO will jump for joy.

Take Me Away

For additional insights into FPC, we spoke to Cuan Hanley, Chief Design Officer at Away and alumnus of familiar brands including Target, Jack Spade and Paul Smith. Cuan’s expereince spans across categories including hardgoods (luggage, in particular) and apparel and accessories, for both men and women.

We asked him about FPC and he gave us his definition of the process:

“I think given by definition of its name, it is a flexible approach in the sense of having multiple levers you can pull from a product development perspective. To be able to maximize a calendar, team resources, geolocation and speed.

A key part of flexible product development is that it allows you pick and choose where and how you want to thoughtfully review development, without being tied to one particular methodology. This is becoming even more important, especially with the continued trend of remote work and not always having people in the same physical spaces”

FPC has a direct impact within the overall supply chain:

“At a high level, supply chain is grounded in time.

It’s time to create something, it’s time to develop it, it’s time to approve it, it’s time to ship it. And when you can narrow those windows in any way, then obviously, that’s an advantage from a supply chain point of view.

I think speed and flexibility are key parts of that as well. If you’re thinking about the apparel product world, just imagine the advantages if you can turn around and approve five new colors virtually, and have it in production quickly. That’s a huge advantage.”

Are there cases where it would not make sense to use FPC?

“I think it may not be as black and white as simply saying there are instances when using FPC would –or would not– make sense.

Of course, seeing the physical sample is always still a desired thing, because it makes it real in a way. So, I think in the occasions where seeing a physical sample is really necessary, that might be when FPC is not an advantage.

But then again, seeing the physical sample is really just one of the different levers you can pull. As an industry, we are kind of moving away from the traditional mentality that everything has to be physical, to having a physical sample being just one of the choices you can pick through the product development done. It’s a very different kind of approach to the whole thing.”

In our chat, we agreed that there is an opportunity within hardgoods to take advantage of 3D printing for prototypes. The advantage being saving the time, cost and effort of physical protos originating from factory. Similar to our conclusions above, these are the types of efforts which lead to incremental improvements in getting brands faster to market.

RSG Highlights From August

Here’s a selection of highlights from the past month:

- Liza sat down for a conversation with Dan Berthiaume, Senior Editor at Chain Store Age, to talk about the struggle of retailer versus excess inventory – click here for the full article.

- We are proud to announce that Liza has joined the Talkdesk’s Retail Industry Advisory Board. Liza joins the board alongside industry leaders from Sephora, Farfetch, Nike and Patagonia. Talkdesk aligns perfectly with our own mission of excellence in retail customer experience while driving process efficiency across product creation and merchandising.

- We’re making a stop in New York City for PI Apparel’s Supply Chain Forum taking place on September 14th and 15th, 2022. Liza takes the stage to talk about flexible product creation and its supply chain implications. Give us a shout if you’re in NYC during mid-September.

- Program information for The Running Event 2022 is now online. Details about our presentations, Going Private (Label) and The Product Assortment Playbook, are now available to view. Perhaps we’ll see you in Austin, TX later this year.