Welcome to The Merchant Life, for retailers and retail enthusiasts wanting the insider perspective of all things retail.

Now let’s talk shop.

Scratch that for today – we put the focus on things outside of the shop and into the supply chain.

Items like coffee, cotton, lumber, leather, chocolate and so on have a lengthy journey before they end up as a product on the shop floor.

How much do we, as an industry, talk about the specifics of that journey? Do we ask the questions of who, what, where, when and how?

We may not have dug deep into our suppliers before but that has surely changed.

Join us as we pull back the curtain and discuss transparency in the supply chain, you might be surprised with what you see.

Walking Blind

Sustainability in retail is a topic of significant conversation within the industry. The scope is broad and encapsulates supply chain transparency.

In our experience, a retailer cannot take meaningful steps towards becoming more sustainable without a clear line of sight into their supply chain.

Here’s the thing – supply chains were never meant to be transparent to begin with.

An article from Harvard Business Review states that “Companies and suppliers have feared that divulging too much information would undermine their competitive advantage or expose them to criticism.”

In other cases, many brands never felt the need to dig deep into their suppliers and understand how their product was being made.

There are probably two reasons why.

- Retailers don’t know what they don’t know. Take myself for instance, as a merchant working for large brands and department stores, I was responsible for building an assortment from product lines presented to me. It never occurred to me to understand the journey of the product. Retail is an inherently siloed business, if sourcing teams were developing transparency in the supply chain, I would have been blind to it.

- Retailers don’t want to know. Legacy relationships with vendors where ruffling feathers would be frowned upon. Combine that with the drive to meet customer demands for faster products and cheaper prices leads to cutting corners. It would be far easier to stay in “business as usual” mode rather than investigate.

Unless they are called out publicly.

Drapers released an article on Feb 8th entitled “The Search for Fashion Supply Chain Transparency” and the details are damning.

Boohoo is accused of paying garment workers in Leicester, UK £3.50 an hour, less than 1/2 of the national minimum wage. While in Pakistan, factories producing clothes for the retailer pay workers £47/month which is below the national minimum wage for unskilled labour.

The CEO has admitted to “a lack of sufficient internal processes.” We believe Boohoo was well aware of these issues.

The recent Xinjiang cotton ban over allegations that cotton is produced under forced labour conditions is another example.

Regarding the ban, Scott Nova, of the Workers Rights Consortium, told the New York Times that “This is a high-decibel wake-up call to any apparel brand that continues to deny the prevalence and problem of forced-labor-produced cotton in the region. This ban will redefine how the apparel industry — from Amazon to Nike to Zara — sources its materials and labor.”

In the same article, there is note that major brands like Nike, H&M, Patagonia and Marks and Spencer have been tied to using cotton from the region; many are severing those ties.

As Mark Morgan, the acting commissioner for U.S. Customs and Border Protection, says very clearly:

“Know your supply chains.”

Simply put, there is no longer an excuse.

As retailers, we have a responsibility to fully understand the conditions in which products are produced.

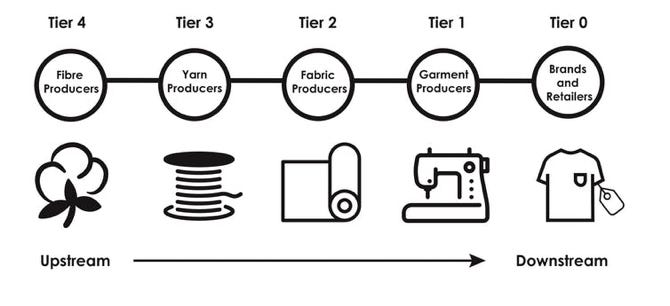

However, most retailers have limited interactions with suppliers beyond the tier 1 level. Relatively speaking, a retailer would have a closer relationship with their manufacturer and fabric mill as opposed to the farmers growing the crop. Below is a simplified diagram of the cotton supply chain – it does not take into account how many different countries where these processes could take place.

The Secret Sauce of Transparency

Experts in Supply Chain, Product Sourcing, Sustainability and Materials Development sat down with us to talk transparency.

One theme stood out in our conversations:

Partnering with your factories is the best way forward.

Valeria Laceria, a leader in sourcing and supply chain, gave us her expert insight based on her time working with brands such as Ralph Lauren and Ann Taylor.

Her main message?

“You must treat your vendors as a true partner. Ask them for their financials, their growth plans, what their objectives are – treat them as a partner.”

It’s very simple; vendors should be viewed as an extension of your brand. They are part of your company just as much as the VP’s who walk the halls.

Why? YOU picked them.

You need to thoroughly vet your partners, as Valeria said:

“These days anyone can go onto Alibaba and source product. There are thousands of vendors that are not transparent. Make sure they can make your product and make sure you can form a bond with them. Enforce the rules, hold your vendor partners accountable, walk the factory floor and find out everything you can about the countries you source in.”

Valeria goes on to provide advice for sourcing pros:

“It is important to understand costing and manufacturing cycles and to only contract on costs and deliveries that can be achieved. Often times vendors are forced into unsustainable practices in an effort to land a program with a leading brand.

I also believe that brands should revisit performance metrics – Being measured on cost and delivery may tempt executives to pressure vendors into making bad choices.”

Heidi Vaughan, a material expert and a former Nike veteran of over 30 years, reinforces this advice with the following:

- Partner with your suppliers – Don’t stop at the garment manufacturer and know who your textile mills are. Make your policies and expectations clear.

- Be selective – Keep your supply chain tight and find out details about the supplier and where they manufacture, if they are a converter, and if they subcontract work.

- Trust but verify – Hold suppliers accountable for meeting your requirements. Facility audits, physical testing, and documentation is necessary.

- Certify – Ensure suppliers have appropriate certifications/documentation. Further, gain commitment that these docs can be provided on demand.

- Remediate or Exit – Implement a remediation plan with your partner to fix problems, if that doesn’t work, then an exit plan is needed.

We also asked Heidi about the impact of the Xinjiang cotton ban.

“The ban of this cotton will have a huge impact on the apparel supply chain. There will be Legal and reputational impact for anyone who hasn’t moved their supply chain, or cannot prove where their cotton products originate from. All of this can lead to disruption in cotton supply – capacity constraints due to less cotton, seizure of shipments by customs and border patrol, impact to cotton pricing due to decreased supply.”

“Cotton can also cross borders several times before landing in final product and this is why transparency can be difficult to manage.”

Tech and Digital Solutions

The adoption of retail tech solutions has accelerated due to the pandemic, we are starting to see more digital tools applied to the supply chain.

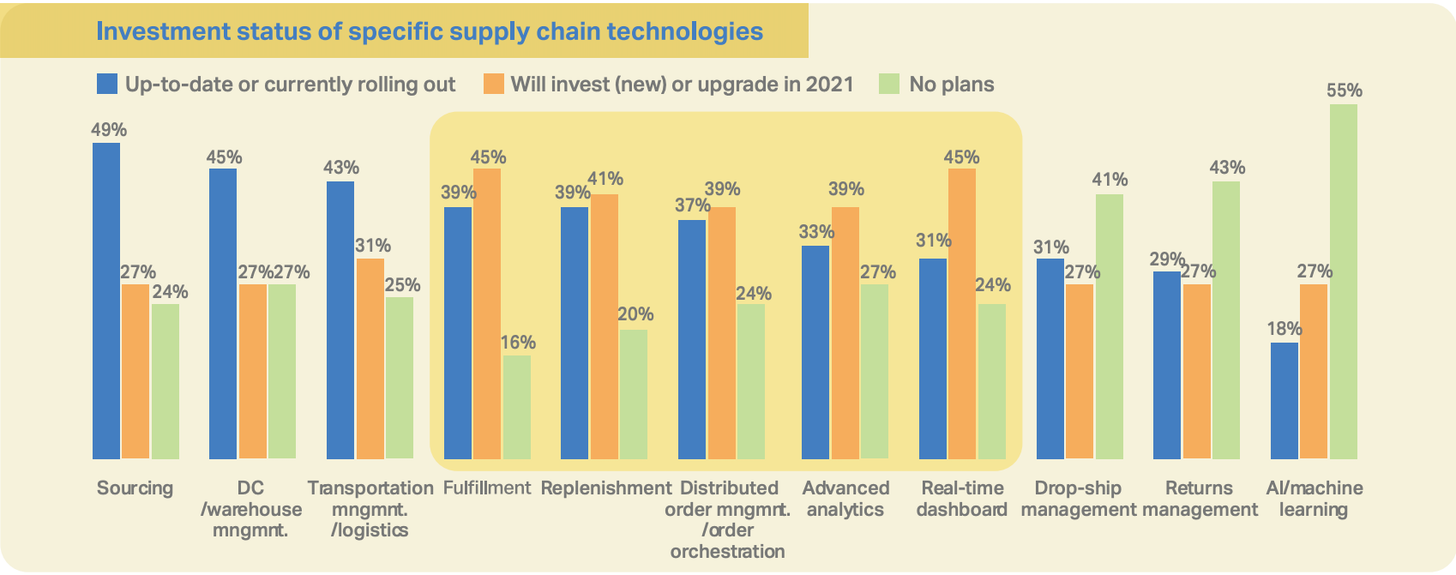

RetailWire’s December 2020 benchmark study on A Major Supply Chain Reset found that 49% of retailers have already or are currently rolling out sourcing technologies; another 27% will be either investing or upgrading this year.

Bext 360 is a SaaS platform provides blockchain traceability and quantifiable measurements for sustainability. We discovered Bext 360 in a 2019 Forbes article describing the Organic Cotton Traceability Pilot. This is a partnership between fashion giants, nonprofits and other tech companies to test if the integrity and authenticity of the organic cotton supply chain can be ensured via the use of blockchain.

The pilot was reported to be a success and this culminated in a display in the Fashion for Good Experience in Amsterdam. There is a featured organic cotton T-shirt from the very supply chain in this project which people can verify in the interactive display.

Other platforms like SourceMap help companies establish supply chain visibility. One example is a recent announcement of a partnership with Ferrero to trace their hazelnut supply chain. You can easily log onto SourceMap to look up high level maps of the supply chains of companies like Vans.

Benefits of Transparency

Partnering with vendors, auditing relationships and investing in technology – it sounds easy, but this is difficult to accomplish. There are many who benefit from the status quo and others will say that this is too costly.

More importantly, if a company achieves an increased level of transparency, the question is what can they do with it? Why should they care?

“Transparency is personal to consumer” says Brittain Ladd, Chief Supply Chain and Marketing Officer at PULSE Integration.

For most consumers, supply chain transparency would be a foreign concept. But caring about the quality of the products they buy and consume is top of mind.

“When it comes to grocery, transparency would mean food and product safety. A grocer can say that we have a sourcing policy to where we only want to source the healthiest and safest product. We know exactly in what field, state and city that broccoli was grown and what the supplier put on it and in what quantity.”

As Ladd describes, this would be an ideal way to build trust, loyalty and repeat business from customers – showing a genuine level of care for customer concern surrounding the products they consume can make a strong emotional connection. Retailers can “Talk the Walk” by broadcasting the benefits of transparency while modeling best practices.

It goes one level higher, where significant amounts of money is shifting. For example, take BlackRock’s 2020 letter to clients entitled “Sustainability as BlackRock’s New Standard for Investing.” They wrote that climate risk can be considered as investment risk, resulting in a significant reallocation of capital. Transparency into the supply chain is necessary to gather the information that investors are now asking for. Without it, there is no ability to assess impact from an environmental and social perspective.

There is no longer an optional or moral imperative to seek out transparency – when capital markets can apply pressure and customers amplify their voice on social media – it’s an absolute necessity.

RSG Insights – No Sample, No Sale.

As a merchant for a department store, I spent days in showrooms and at trade shows. If I didn’t have a sample then I would most likely not invest in that collection. Unless I trusted my vendor implicitly and was buying repeat styles, I always asked to see a physical sample.

The reason was always the same – we need to touch & feel the collection.

It’s not a new concept – buying is predominantly a physical experience.

If there was no sample, there was no sale.

Sampling has always been a pain point for most brands and retailers.

- Sampling is pricey – minimal order and shipping quantities.

- You need more than one sample set for each market.

- Having a sample does not always equate to a sale.

As consumers have embraced e-commerce, buyers are starting to do the same.

The pandemic has forced us to reexamine the sample supply chain, how much we spend on samples, shipping from city to city, travelling to market – we impact the climate and waste time and money.

By flipping to digital, you increase go-to-market speed as there is no need to wait for samples to approve an assortment.

Unless you are brand that needs to fit a new innovative style, you don’t need a sample.

The takeaway?

The pandemic has shown us that we can all work with digital tools.

Challenge traditional methods of buying and get to market faster.