Welcome to The Merchant Life, for retailers and retail enthusiasts wanting the insider perspective of all things retail.

Now let’s talk shop.

Speed to market and getting closer to your customer goes hand in hand.

The faster you can get your products in front of your customer, the faster you give them what they want before they need it.

The secret to getting faster to market?

Not all product is created equally.

This week, we break down how products are traditionally created and how to leverage inequality to generate speed.

Lace up your running shoes, we’re off to the races!

Old School

Let’s outline the traditional process of creating product.

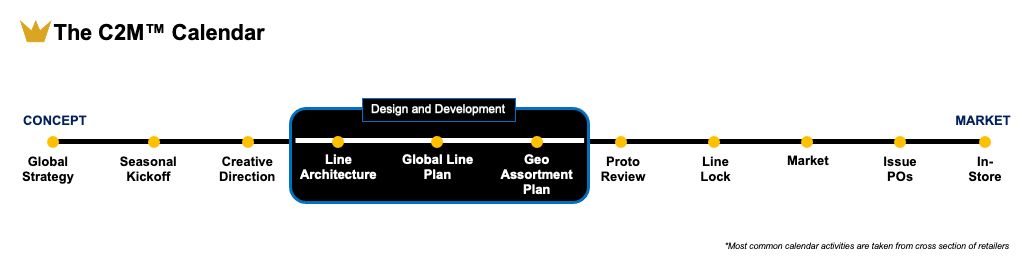

It starts with the calendar —> from strategy to concept to go to market, the seasonal calendar holds your line plan, in addition to the activities associated with launching products for each season.

The building blocks that make up the line plan hold all the details of your assortment, from new items to carryover styles, from material selection to color, from depth by style to global distribution.

Below you will find a typical calendar of moments gathered from the many retailers I’ve worked with. The activities are aligned whether you are a design led wholesale/retail brand or a department store like Nordstrom or The Bay.

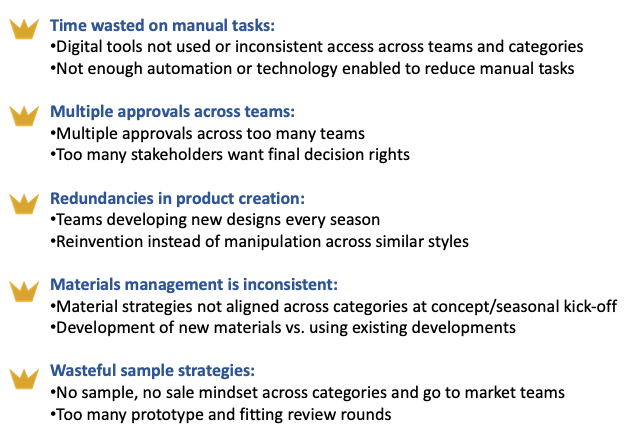

There is a considerable amount of tension that is introduced here because of the following:

- Customers expect speed. We can call this the “Amazon Effect” as consumers want things essentially on demand.

- Retailers are working within outdated processes supporting product creation and merchandise selection – there is no ability to accelerate.

- The calendar can range from 55 weeks to 2 years from concept to market. In simple terms, it takes at least a year for new products to hit the market.

That’s right. A year to market and no flexibility to react to customer shopping behaviors.

Here are some of the barriers are currently in place which prevent acceleration:

Speed to market is a key focus for retailers today and getting faster to market must involve an overhaul of the product creation process.

This is where the idea of “Acceptable Inequality” can be introduced – this revolves around the concept of not all products are created equally.

New School

Riddle me this…

In your assortment you have carryover or basic styles like a long sleeve t-shirt. Let’s also assume that you have a brand new, innovative top with a technical textile never used previously.

You also have one calendar with a single line plan.

Here is an example of how we can shift the way we look at product using product complexity:

So what does this mean?

All types of products do not require the same skillsets, resources or TIME to develop. Furthermore, not all products require the same number of prototypes or samples.

Meaning, that not all products need to be created in the same way.

Well it’s actually when art meets science.

If we examine how much time each product needs from concept to market, you can prioritize when product needs to be developed and when it doesn’t.

It all comes down to planning.

Leverage calendar activities to spend more time on newness versus non-complex styles.

Speed to Market – Guiding Principles

Getting closer to your customer with speed by optimizing calendar activities, simplifying product creation methods, and evolving materials/sample management.

Here are a few guiding principles to get started in driving efficiencies in product creation.

1 – Simplify the way you work

- Stagger product creation as not all products require the same effort and add innovative product development into your line plan. This way, teams can spend time on products that will help differentiate you from other retailers and brands.

- Involve your customer in validating your products before you finalize your product assortment.

2 – Remove redundancies and eliminate manual tasks. Partner with cross-functional teams and align on insights + seasonal strategies up front.

- Involving all teams to level set on the seasonal strategy at concept dramatically reduces time wasted.

- Enable technology in product creation and align on the right digital tools to use. 3D printing is a good example.

- Unlock predictive analytics to remove the guesswork across demand planning – develop the right product at the right time.

3 – Think of your vendors, factories and cross-functional teams as your real partners. Strengthen these relationships to go faster to market.

- Give your factories autonomy to fit and test product for you and reduce the time and money wasted on sampling.

- Align digital tools with factories and overseas teams to avoid guesswork that comes with manual drawings and designs.

- Create a digital and physical materials library to eliminate overdevelopment and redundant tasks.

There you have it.

A few ideas to get you faster to market.

Just like one size doesn’t fit us all, not all products should be created equally.

The Finish Line

Revisiting the way you create product allows you to focus on high priority work such as innovative product creation.

Strategize at the start of the season, work with your partners and give them autonomy to make decisions for you.

Finally, devote resources on what takes the longest will set you apart from your competition.

All of this equates to acceleration to get product into market and how to thrive in retail today.