If we go back to some old-school Peter Drucker, we find that he has identified 10 areas of innovation.

Four examples include:

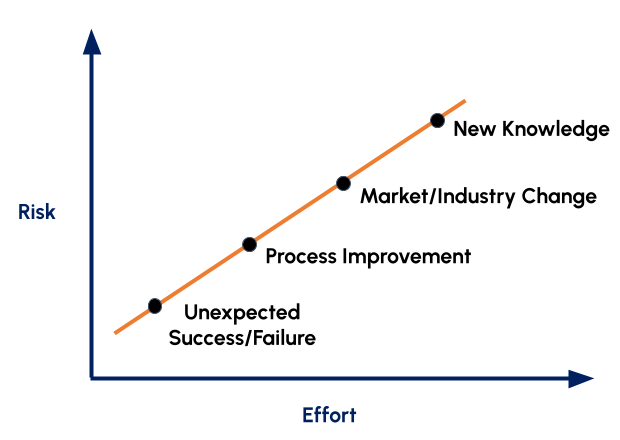

1 – New Knowledge. This is the domain of next-gen materials. It’s the riskiest path: long lead times, high failure rates, and it attracts all the hype and capital. We can look to examples like Natural Fiber Welding and Renewcell as examples of what can happen in the realm of new material innovation.

2 – Market/Industry Changes. As the market shifts, opportunities to innovate emerge. Usually, the big players are blind to these changes. Challenger brands exploit the gaps that incumbents miss. Lululemon (boring) vs. Vuori (not boring) as an example. Brands have to work hard to maintain market visibility.

3 – Improving Process Weakness. For example, starting with materials (like pre-existing and banked fabric and color) first instead of design first. Process fixes improve margin without selling more. It also curbs chronic overdevelopment which (checks notes) is also a sustainable outcome. For more information about this topic, make sure to buy our upcoming book: The Material Life – Process Innovation for Retailers and Brands, releasing in December.

4 – Unexpected Failure/Success. According to Drucker, these opportunities are often ignored and are highly productive. A fabric or color that failed in one application could very well succeed with another. Why engineer fabric from scratch when a vendor may already have a development that fits the bill.

The risk/effort relationship for these types of innovation are displayed in the graph below:

All companies are well served by engaging in several of these forms of innovation to reach their goals. These goals can be related to profitability, margin, sustainability or any combination of the three.

Each company can judge the risk/effort relationship with each one accordingly. Then, make decisions as to where to invest effort and to what extent.